Contact HighSight Team

Your email ID will not be used for any other purpose.

I. Core Basics of UPVC Pipe Fittings:

A. Material Characteristics: UPVC (unplasticized polyvinyl chloride) pipe fittings are corrosion-resistant (against acids, alkalis, and salts), lightweight, and have good insulation properties. They are not resistant to high temperatures (long-term use temperature ≤ 60°C) and are prone to brittleness at low temperatures (special care needed below -10°C).

B. Applicable Scenarios: Mainly used for water supply and drainage (cold water), chemical pipelines, and building wiring conduits. They are prohibited for use in hot water pipelines (as they are prone to deformation and aging).

1.Potable water (cold water) applications

2.Industrial-grade application scenarios

II. Key Technical Parameters

A. Pressure Rating: Common grades are PN1.0/1.6 MPa (corresponding to working pressures of 10/16 kg/cm²). It must match the pipeline system pressure to avoid overpressure and leakage.

B. Specifications and Sizes:

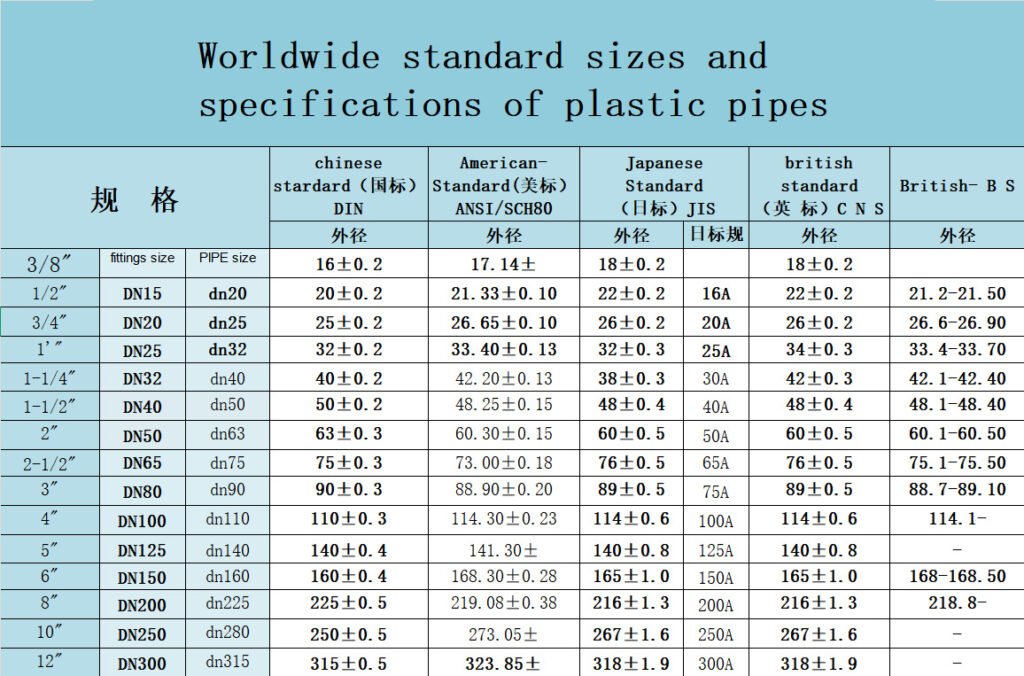

1)Nominal Diameter (DN): DN15/20/25/32/40/50/63, etc. (corresponding to common imperial sizes such as “1/2”, “3/4”, “1” …).

II. Key Technical Parameters

A. Pressure Rating: Common grades are PN1.0/1.6 MPa (corresponding to working pressures of 10/16 kg/cm²). It must match the pipeline system pressure to avoid overpressure and leakage.

B. Specifications and Sizes:

III. Quality Assessment

IV. Installation and Usage Notes

V. Common Issues and Mitigation

Leakage: Often caused by unclean joints, uneven solvent cement application, or water flow before full curing. Solution: Strictly follow the cementing procedure; allow curing time ≥ 24 hours.

Cracking: Caused by impact at low temperatures, overpressure operation, or insufficient wall thickness. Solution: Select fittings with adequate pressure margin; handle gently during winter installation.

Blockage: Caused by residual debris in pipes or insufficient slope. Solution: Clean pipes before installation; ensure a minimum slope of ≥ 3‰ for drainage pipes.